If you notice your oil level is going up over time, that’s a dead giveaway the injectors are leaking, but usually it won’t be enough to notice on the dipstick.

#Piezo injector conversion lb7 cracked#

A failing LB7 injector will allow excess fuel into the engine either from a leaky pintle seat or a cracked body, but in either case, that fuel can wind up where it doesn’t belong. If you see gray smoke or “haze” from the tail pipe, that’s never a good sign you must investigate the injectors further.

#Piezo injector conversion lb7 driver#

The first visual clue a driver will notice will be excessive smoke from the tail pipe at idle. The truth is you could toss a coin and have a fair chance of deciding that your LB7 needs a set of injectors, but there is of course a very scientific way to determine which ones are failing. Sadly, there are many injectors that will fail after the warranty period has expired, but thankfully there is plenty of aftermarket support for the problem. There must have been hundreds of thousands of LB7 injectors replaced under warranty, and they even extended the coverage on LB7 injector replacement for seven years and 200,000 miles at no cost to the owner. GM figured this out quickly, and they stood behind their product. The tip of the injector sits directly inside the combustion chamber where it sees extreme temperature and pressure, and the inside of the injector sees well over 24,000 PSI of fuel, and the pintle is moving back and forth constantly, and over time these harsh conditions can cause a failure of the injectors. While the LB7 is a reliable powerplant, over time, it began to show its weakness.

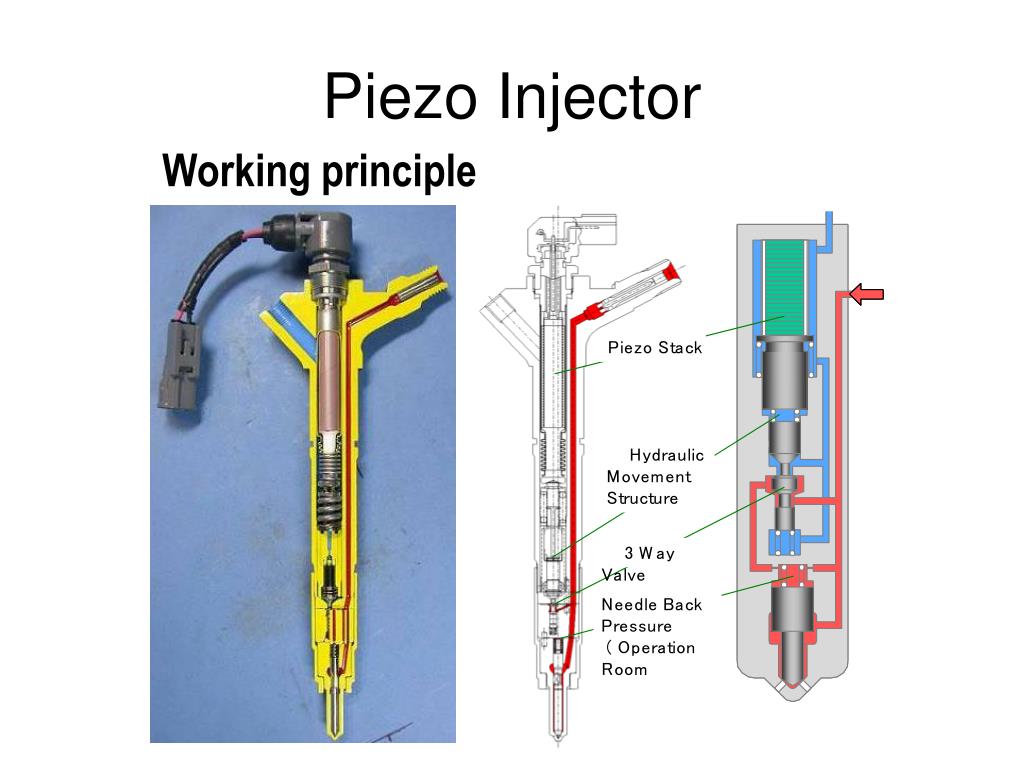

of torque, which made it extremely popular with truck owners in the early 2000s. While the numbers may not seem that impressive by today’s standards, the LB7 Duramax produced a best of 300 horsepower and 520 lb.ft. As emissions regulation increased and the consumers demand for towing power at the turn of the century, the benefit of a common-rail diesel became readily apparent. The beauty of a common-rail injection system is it can atomize the fuel into a much smaller droplet, and the ECM has greater control over the timing and amount of fuel, which means more power and efficiency compared to previous injection designs. Inside the injector is a small pintle valve that opens and shuts to deliver fuel in the precise quantity, and it’s all actuated by an electrical solenoid (or by a piezoelectric crystal in later model trucks, but that’s a conversation for a different time). Between the injection pump and the injectors is a fuel rail which distributes fuel to all cylinders, and fuel flows between them through steel connector tubes. There is an injection pump which creates the high-pressure fuel, and injectors that deliver fuel directly into the combustion chamber. The First Common-RailĮvery common-rail diesel engine has the same basic parts to its fuel system, whether it’s a Cummins, Powerstroke, or Duramax. So, to help LB7 owners keep their beloved diesel on the road for another 20 years, we’re breaking down the right way to diagnose and repair failing LB7 injectors. If you own a 2001 to 2004 LB7 Duramax powered rig, there is a pretty good chance the injectors have already been replaced at some point, but there are still many trucks operating today that will experience injector problems. Unfortunately, fuel injector failure was a very common problem with the new powerplant. The LB7 Duramax used an innovative design to get fuel into the combustion chamber, and their R&D paved the way for Ram and Ford to follow a few years later.

This was exactly what happened to GM when they introduced the world’s first high-pressure common-rail direct-injected diesel engine (in a pickup truck) back in 2001.

Sometimes when you’re the first to market with a new product, there are growing pains that come along with your innovative design that take a while to work through.

0 kommentar(er)

0 kommentar(er)